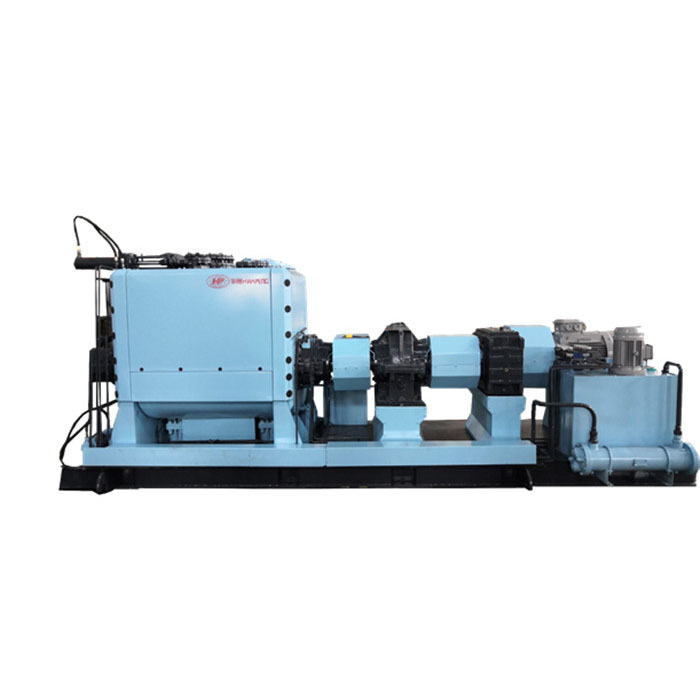

HP-H(H)KC High Efficient Preheating Kneading Cooling System rau Tshwj Xeeb Graphite

HP-H (H) KC Series High Efficient Preheating Kneading Cooling System yog tsuas yog siv nyob rau hauv kev npaj muab tshuaj txhuam hauv kev lag luam carbon, rau zus tau tej cov prebaked anode, txhuas cathode, graphite electrode, tshwj xeeb graphite thiab lwm yam khoom.Tom qab sib sau ua ke yog rhuab mus rau cov txheej txheem teev kub nyob rau hauv lub tshuab preheating, nws nkag mus rau hauv lub tshuab kneading kom tiav cov kneading ntawm cov khoom qhuav thiab cov binder suab, sib sau muab tshuaj txhuam nrog zoo plasticity, thiab cov muab tshuaj txhuam nkag mus rau hauv lub tshuab cua txias kom txias rau. cov txheej txheem txheej txheem kub.

HP-H (H) KC High Efficient Preheating Kneading Cooling System yog nruab nrog lub tank kub-kub tshiab, ua haujlwm siab kub sib xyaw hniav, kev saib xyuas kev nyab xeeb ntawm kev sib koom ua ke, cov khoom sib khi tshiab ntawm kev sib xyaw hniav ncej kawg, kev tiv thaiv kev nyab xeeb. cov cuab yeej ntawm cov hniav sib xyaw, lub sijhawm saib xyuas qhov system ntawm cov hniav sib xyaw, lub suab tsis sib xws pub khoom noj, kis tau tus mob nrog lub peev xwm muaj peev xwm thiab txhim khu kev lag luam, yooj yim hloov cov phaj phaj, ntsuas qhov ntsuas kub, thiab lwm yam, kom ntseeg tau tias kev ua haujlwm ntawm cov cuab yeej siv tau zoo. , ruaj khov thiab txhim khu kev qha.

Kev ua tau zoo

Tom qab kev kho saum npoo, qhov roughness ntawm qhov nkhaus thiab qhov chaw ntawm cov hniav sib tov ncav cuag 0.1, cov khoom sib tov thiab cov khoom txias yog sib txawv, tsis yooj yim rau lo rau cov hniav sib tov, thiab kev pab cuam lub neej ntawm cov hniav sib tov yog 20 xyoo.

Nws tau txais cov cuab yeej tshiab txuas ntxiv ua haujlwm siab, kev ua haujlwm siab-kub tank patent thev naus laus zis, sib xyaw cov hniav cua sov patent thev naus laus zis, kev sib xyaw hniav tshiab cua sov patent thev naus laus zis thiab tag nrho cheeb tsam cua sov patented thev naus laus zis.Cov khoom siv qhuav muaj cua sov ceev ceev thiab ua haujlwm kub kub.

Cov khoom sib xyaw qhuav ua ntej cua sov siv tangent, sib txawv ceev thiab lub vojvoog qhuav cov khoom sib xyaw thiab cua sov tshuab kom sib xyaw cov ntaub ntawv sib npaug.

Lub paste kneading adopts intersectant synchronous mixing hniav, overlying mixing technology.Cov ntaub ntawv yog kneaded tusyees tsis kneading qhov muag tsis pom lub kaum sab xis thiab thaiv raw khoom.

Nruab nrog cov plua plav collector los sau cov plua plav tawm thaum lub sij hawm qhuav cov khoom noj hauv cov txheej txheem sib xyaw qhuav thiab tiv thaiv ib puag ncig.Cov plua plav uas tau khaws cia yuav rov qab tuaj yeem thiab txuas ntxiv mus koom rau hauv cov txheej txheem sib xyaw qhuav kom ntseeg tau qhov sib npaug ntawm cov ntaub ntawv thiab cov khoom zoo.

patented thev naus laus zis ntawm kev ntsuas kub ntsuas kub tshiab tau txais los ua, nrog kev ntsuas qhov tseeb thiab ntsuas qhov ntsuas kub ntawm ± 2 ℃.

Cov patented ua ke sib tshooj hlau nplhaib foob tshuab tau txais kev pom zoo los xyuas kom meej tias tsis muaj cov pa roj carbon monoxide tawm ntawm qhov kawg ntawm cov hniav sib xyaw.

Lub tank yog ua los ntawm qis-alloy high-strength steel phaj Q460D.Sab hauv ntawm lub tank yog kho nrog qhov roughness ntawm 0.1.Cov ntaub ntawv tsis yooj yim rau lo rau lub tank.Lub neej ua haujlwm ntawm lub tank yog 20 xyoo.

Hnav resistant welding txheej yog overlayed rau saum npoo ntawm cov hniav sib tov, thiab cov kev pab cuam lub neej ntawm cov hniav sib tov yog 20 xyoo.

Lub unloading system txais hydraulic turnover los xauv lub qhov rooj unloading kom tsis txhob muaj cov ntaub ntawv to.Lub tank thiab tawm rooj vag yuav tsum tsis txhob xau carbon nplua hmoov.

Cov hniav sib xyaw yog tsim los ua kom txav tau los tiv thaiv cov hniav sib xyaw los ntawm kev ua kom sov, txuas ntxiv thiab daig; Cov hniav sib xyaw yog nruab nrog ob-txoj kev thrust bearing los tiv thaiv cov hniav sib tsoo los ntawm kev sib tsoo lub tank.

Lub tank muaj cov qauv sib cais, thiab qhov chaw noj mov thiab qhov chaw khaws plua plav yog khaws cia rau saum lub hau.

Nruab nrog lub sijhawm saib xyuas qhov system rau lub ntsiab bearing kub ntawm lub ntsiab cav, tswb tam sim ntawd nyob rau hauv cov ntaub ntawv ntawm abnormality.Lub ntsiab ncej bearing txias thiab xyuas qhov system yog nruab rau txias lub ntsiab ncej bearings nyob rau hauv lub sij hawm, saib xyuas cov cua txias nruab nrab kub, ntws thiab lwm yam tsis raws sijhawm, thiab muab lub tswb nrov tam sim ntawd thaum muaj qhov txawv txav.Ua kom muaj kev nyab xeeb, txhim khu kev qha thiab ruaj khov ua haujlwm ntawm spindle-bearing system nyob rau hauv qhov kub thiab txias.

Nruab nrog kev sib xyaw cov hniav kev ruaj ntseg tiv thaiv ntaus ntawv. Txiav tawm lub zog tam sim ntawd los tiv thaiv cov hniav sib tov los ntawm kev puas tsuaj nyob rau hauv cov ntaub ntawv ntawm overloading.Tom qab lub load rov qab mus rau qhov qub, ncaj qha pib lub ntsiab lub cev muaj zog, cov cuab yeej tiv thaiv kev nyab xeeb cia li sib txuas thiab rov ua kom lub zog, thiab lub kaw lus rov ua haujlwm li qub.

Technical Parameters

| Tshwj xeeb graphite qhuav khoom preheating tshuab | HP-DMH(H)600-SG | HP-DMH(H) 2000-SG | HP-DMH(H) 3000-SG |

| Rated ntim (L) | 600 | 2000 | 3000 |

| Qhov siab tshaj plaws (L) | 1150 | ib 3680 | 3900 ib |

| Lub kiv puag ncig ntawm Mixing Blade (RPM) | 16/13 | 12/15 | 12/15 |

| Txoj Kev Kub Kub | Thaum tshav kub kub hloov roj | Thaum tshav kub kub hloov roj | Thaum tshav kub kub hloov roj |

| Ua haujlwm siab (MPA) | 0.3 | 0.3-0.4 hli | 0.3-0.4 hli |

| Txoj Kev Kneading | tangent sib txawv velocity radius | Sib txawv tangent radius | tangent sib txawv velocity radius |

| Tshwj xeeb Graphite Kneader | HP-CPK600-SG | HP-CPK2000-SG | HP-CPK3000-SG |

| Rated ntim (L) | 600 | 2000 | 3000 |

| Qhov siab tshaj plaws (L) | 1000 | 3 450 | 4800 ib |

| Txoj Kev Kneading | Kev sib tshuam tib yam tshaj tawm superradius | Kev sib tshuam tib yam tshaj tawm superradius | Kev sib tshuam tib yam tshaj tawm superradius |

| Lub kiv puag ncig ntawm Mixing Blade (RPM) | 16 ~ 32 (kho tau) | 16 ~ 32 (kho tau) | 12 ~ 18 (kho tau) |

| Txoj Kev Kub Kub | Thaum tshav kub kub hloov roj | Thaum tshav kub kub hloov roj | Thaum tshav kub kub hloov roj |

| Ua haujlwm siab (MPA) | 0.3 | 0.3-0.4 hli | 0.3-0.4 hli |

| Tshwj xeeb Graphite Paste Kneading Cooler | HP-PKC600-SG | HP-PKC2000-SG | HP-PKC3000-SG |

| Rated ntim (L) | 600 | 2000 | 3000 |

| Qhov siab tshaj plaws (L) | 1000 | ib 3850 | 5 200 |

| Lub kiv puag ncig ntawm Mixing Blade (RPM) | 5 ~ 10 (kho tau) | 5 ~ 10 (kho tau) | 5 ~ 10 (kho tau) |

| Kev sib xyaw | Kev sib tshuam tib yam tshaj tawm superradius | Kev sib tshuam tib yam tshaj tawm superradius | Kev sib tshuam tib yam tshaj tawm superradius |

| Txoj kev txias | dej txias | dej txias | dej txias |

| Ua haujlwm siab (MPA) | 0.3 | 0.3-0.4 hli | 0.3-0.4 hli |