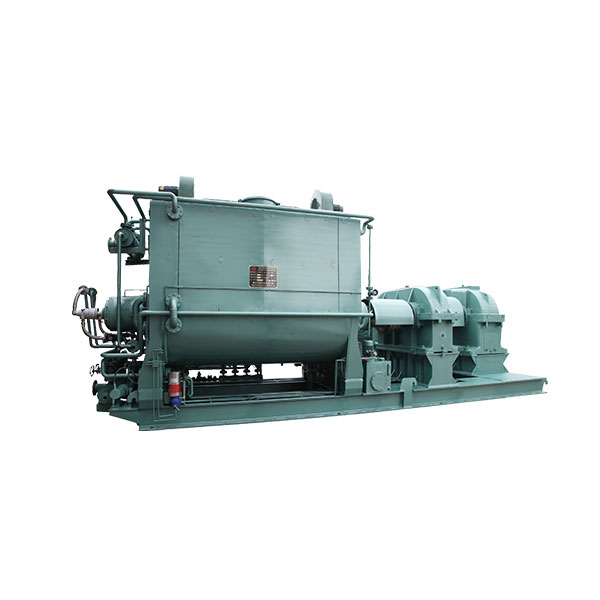

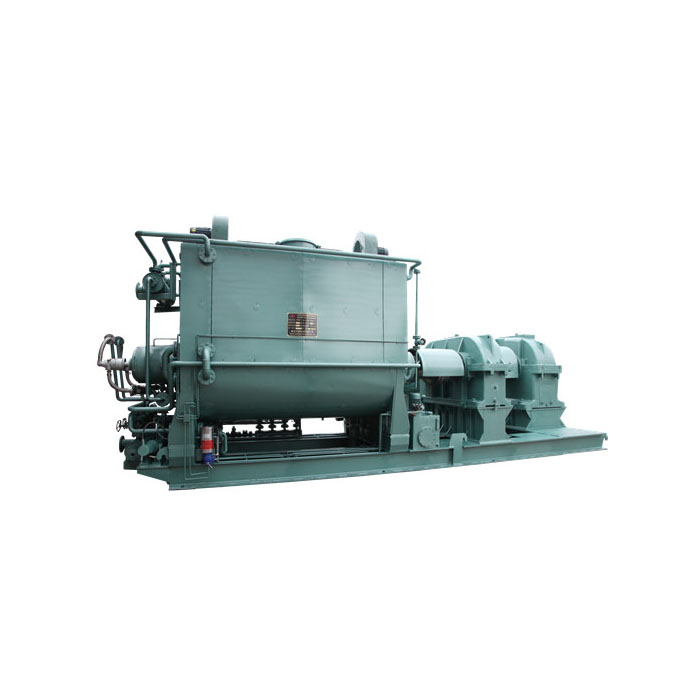

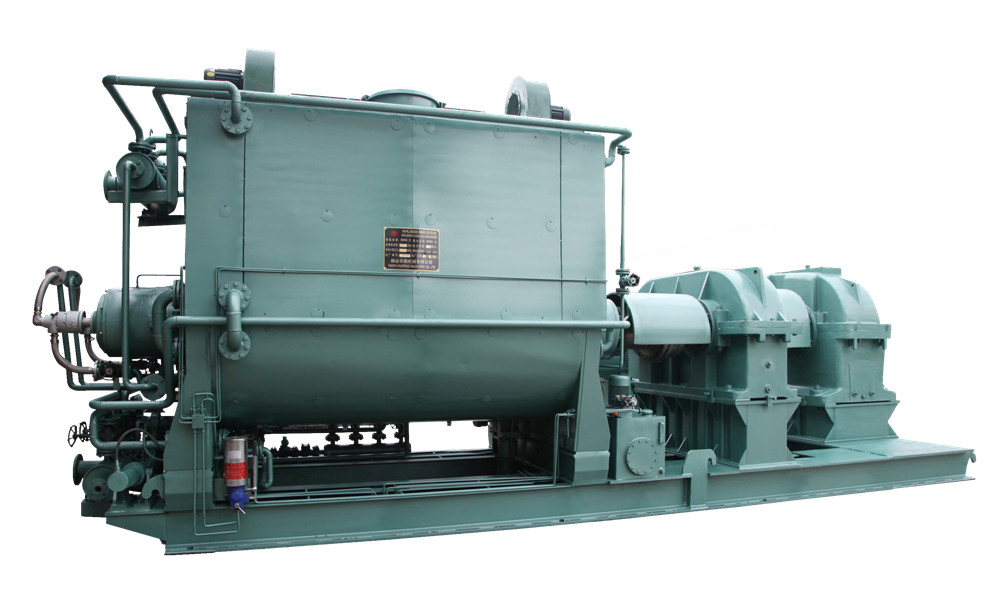

HP-H(H)KC High Efficient Preheating Kneading Cooling System

HP-H (H) KC Series High Efficient Preheating Kneading Cooling System yog tsuas yog siv nyob rau hauv kev npaj muab tshuaj txhuam hauv kev lag luam carbon, rau zus tau tej cov prebaked anode, txhuas cathode, graphite electrode, tshwj xeeb graphite thiab lwm yam khoom.Tom qab sib sau ua ke yog rhuab mus rau cov txheej txheem teev kub nyob rau hauv lub tshuab preheating, nws nkag mus rau hauv lub tshuab kneading kom tiav cov kneading ntawm cov khoom qhuav thiab cov binder suab, sib sau muab tshuaj txhuam nrog zoo plasticity, thiab cov muab tshuaj txhuam nkag mus rau hauv lub tshuab cua txias kom txias rau. cov txheej txheem txheej txheem kub.

HP-H (H) KC High Efficient Preheating Kneading Cooling System yog nruab nrog lub tank kub-kub tshiab, ua haujlwm siab kub sib xyaw hniav, kev saib xyuas kev nyab xeeb ntawm kev sib koom ua ke, cov khoom sib khi tshiab ntawm kev sib xyaw hniav ncej kawg, kev tiv thaiv kev nyab xeeb. cov cuab yeej ntawm cov hniav sib xyaw, lub sijhawm saib xyuas qhov system ntawm cov hniav sib xyaw, lub suab tsis sib xws pub khoom noj, kis tau tus mob nrog lub peev xwm muaj peev xwm thiab txhim khu kev lag luam, yooj yim hloov cov phaj phaj, ntsuas qhov ntsuas kub, thiab lwm yam, kom ntseeg tau tias kev ua haujlwm ntawm cov cuab yeej siv tau zoo. , ruaj khov thiab txhim khu kev qha.

HP-DMH SERIES

QHOV CHAW UA HAUJ LWM PREHEATER

Kev siv tshuab ua kom muaj zog-ua kom sov ntau, cov ntaub ntawv qhuav tuaj yeem ua kom sov txog 180 ℃ hauv 30min thaum HTM yog 260 ℃.

Kev ua tau zoo

1. High preheating zoo

Nws txais cov tangent thiab sib txawv sib xyaw cov hniav qhuav cov khoom sib xyaw thiab cov tshuab cua sov, los ntawm cov khoom siv lossi hu rau cov khoom siv hluav taws xob sib txuas ncaj qha kom paub qhov sib xyaw thiab cua sov.

2.Kev xa hluav taws xob ceev ceev thiab kub siab

Txais kev kub siab tank patent technology (invention patent naj npawb: ZL201210124643.8), hom tshiab sib tov hniav patent technology (Patent No.: ZL 201610897074.9, ZL201610897263.6), tag nrho cov cua sov patent tooj: ZL2020 patent technology. sib tov hniav cua sov patent technology (patent tooj: ZL200620085174.3), tso tawm rooj vag cua sov tshuab hauv ob sab phlu thiab tank seamless haum tshuab.

3. Guarantee qhuav khoom particle loj proportions

Siv cov cuab yeej tshwj xeeb los ua cov txheej txheem sab hauv ntawm lub tank thiab cov kabmob qhov ntawm lub tank kawg phaj, lub siab machining precision guarantees qhov sib txawv ntawm kev sib xyaw hniav thiab lub tank thiab tiv thaiv cov khoom los ntawm kev sib tsoo thaum sib tov thiab cua sov.

4. Kev ntsuas kub yog qhov tseeb

Txais cov cuab yeej ntsuas kub tshiab (patent No.: ZL201420490132.2) txhawm rau txhim kho qhov ntsuas kub ntawm qhov ntsuas kub thiab tiv thaiv kev cuam tshuam.

5. Zoo meej huab cua nruj

Txais kev sib koom ua ke sib tshooj hlau nplhaib los tsim ntau qhov sib khi (patent naj npawb: ZL 2014 2 0490187.3) kom lav tsis muaj cov pa roj carbon monoxide los ntawm qhov kawg ntawm cov hniav sib xyaw;Hydraulic rotary lock discharge rooj vag muaj huab cua zoo heev, sealing nto uas yuav tsis hnav tawm tias huab cua nruj yog txhim khu kev qha uas tsis muaj cov khoom xau los ntawm lub qhov rooj tawm.

6. Ceev ceev, tsis muaj cov khoom seem

Sib tov cov hniav thawb cov khoom spirally kom tawm sai.Cov khoom raug tshem tawm tag nrho los ntawm lub qhov rooj tawm hauv qab hauv tsawg dua 2min yam tsis muaj seem seem.

7. Tsis muaj hmoov to thaum lub sij hawm xa khoom

Sealing hopper seals tawm qhov rooj kom tiav, tsis muaj hmoov nkag thaum cov khoom tawm.Tag nrho cov hydraulic tswj mechanisms ntawm qhov rooj tawm yog teem sab nraum sealing hopper kom yooj yim saib thiab tu.

8. Siab hnav-tiv taus hauv ob sab phlu

Sib tov cov hniav yog nto-welded nrog hnav-resistant khaubncaws sab nraud povtseg, rigidity yog mus txog rau HRC665, thiab kev pab cuam lub neej ntawm sib tov hniav yog 20 xyoo.Hom tshiab hnav-resistant manganese steel cov ntaub ntawv yog siv los ua hauv ob sab phlu nrog lub zog siab tom qab kev kho cua sov.Kev pabcuam lub neej ntawm cov phaj phaj rau cov khoom siv anode yog 15 xyoo thiab 1 xyoos nws yog rau cathode thiab carbon electrode ntau lawm.

9. Kev sib xyaw hniav qauv tsim nyog rau qhov chaw ua haujlwm kub kub

Cov kabmob txav thaum sib tov hniav ncab ntev dua nyob rau hauv tshav kub kom tsis txhob muaj cov kab nrib pleb uas tshwm sim los ntawm kev sib xyaw hniav ntev dua.Bearing chamber muaj cov qauv cua txias uas lav qhov ua haujlwm kub ntawm cov kabmob thiab nws txuas ntxiv kev pabcuam lub neej ntawm cov kabmob Bearing chamber muaj lub tsho dej txias los lav kev ua haujlwm kub ntawm cov kabmob hauv qab kub thiab txuas ntxiv nws lub neej kev pabcuam.Cov hniav sib xyaw ua haujlwm ib txwm nyob rau hauv qhov kub thiab txias.

10. Txhim khu kev ua haujlwm ntawm kev sib kis

Cov kab ke sib kis yog tsim los ntawm tus tswv lub cev muaj zog, P series tawv hniav txo cov iav, cov kabmob muaj peev xwm ntawm 3 npaug ntawm cov hniav txo cov iav, yog li cov cuab yeej yuav tsis raug puas ntsoog nyob rau hauv rooj plaub ntawm txawv teb chaws cov khoom poob rau hauv lub tank thiab thaiv cov hniav sib xyaw. .

11. Tsis muaj suab nrov

Nws yog machined los ntawm cov cuab yeej tshwj xeeb, nws muaj qhov zoo sib xws, kev ua haujlwm yog du, kev pab cuam lub neej ntev, thiab lub suab nrov ntawm tag nrho lub tshuab yog tsawg dua 80dB.

12.PLC tag nrho tsis siv neeg tswj

PLC tswj thiab kev sib txuas lus hauv internet tau txais los ntsuas cov zaub thiab xa cov khoom siv khiav thiab cov xwm txheej ntawm lub sijhawm (optional configuration).Peb hom kev lag luam--internet tsis siv neeg, ib lub tshuab tsis siv neeg thiab tswj--ua kom lub tshuab nws tus kheej tuaj yeem khiav tau txawm tias cov tshuab ntws thiab qis qis tsis siv neeg.

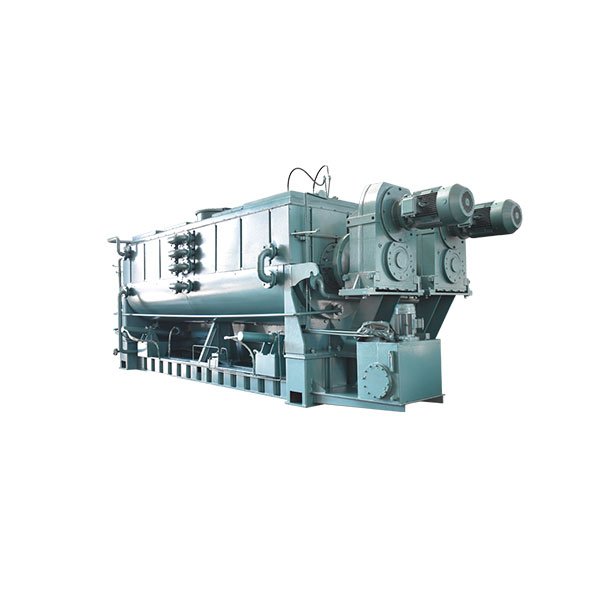

HP-CPK SERIES

CARBON PASTE KNEADER

HP-CPK Series Carbon Paste Kneader (invention patent naj npawb: ZL20141 0430160.X,ZL201420490132.2) txais ntau cov patented technologies, uas lav zoo heev paste kneading zoo, zoo sealing kev ua tau zoo uas tsis muaj plua plav thiab pitch pa taws to.

Kev ua tau zoo

1. Kev sib xyaw ua ke zoo

Nws txais kev sib tshuam, synchronous sib xyaw hniav tshuab los ntawm Nyiv.Sib tov cov hniav vojvoog tshaj qhov nruab nrab ntawm lub tank uas ua rau thaj tsam loj;ob qhov sib xyaw cov hniav muaj tib lub voj voog nce toj kev taw qhia tab sis sib txawv cov kev taw qhia, ib qho sib xyaw cov hniav thawb cov khoom mus rau hauv nruab nrab thiab lwm tus thawb mus rau ob sab, cov khoom ntws zoo li "8" hauv lub tank.

Cov seem ntawm cov hniav yog elliptic uas thawb cov ntaub ntawv kom txav mus nrog ntsug kev taw qhia ntawm elliptic seem, squeezing kev txiav txim yog intensified, cov khoom granules yog tag nrho tov, mixing thiab kneading nyhuv yog ntxiv dag zog.Elliptic seem tsis lo rau cov khoom yooj yim thiab nto. ntawm cov hniav sib tov yog dawb ntawm cov ntaub ntawv.

2.Kev xa hluav taws xob ceev ceev thiab kub siab

Txais kev kub siab tank patent technology (invention patent naj npawb: ZL 2012 1 0124643.8) (qhov no yog customized configuration), zuag qhia tag nrho cov cua sov patent technology (invention patent tooj: ZL2004 2 0018996.0), mixing blade in heating 06 patent patent technology 2 0085174.3) (qhov no yog kev teeb tsa kev cai), tso tawm rooj vag cua sov tshuab, hauv ob sab phlu thiab tank seamless txuas tshuab.

3. Guarantee qhuav khoom particle loj Proportion

Siv cov cuab yeej tshwj xeeb los ua cov txheej txheem sab hauv ntawm lub tank thiab cov kabmob qhov ntawm lub tank kawg phaj, machining precision yog siab thiab nws lav qhov yuav tsum tau sib txawv ntawm kev sib xyaw cov hniav thiab lub tank kom tsis txhob muaj qhov sib tsoo thaum sib tov qhuav thiab cua sov.

4. Pitch tis yog uniform

Pitch distribution device yog mounted rau ntawm lub hau kom ntxiv suab rau hauv lub tank uniformly los ntawm ntau lub ntsiab lus, suav nrog cov khoom qhuav thaiv hauv paste yog zam.Cov cuab yeej yog rhuab los ntawm tshav kub hloov roj kom tsis txhob solidified pitch thaiv cov cuab yeej.

5.Kev ntsuas kub yog qhov tseeb

Txais cov cuab yeej ntsuas kub tshiab (patent No.:Z2014 2 0490132.2) txhawm rau txhim kho qhov ntsuas kub ntawm qhov ntsuas kub thiab tiv thaiv kev cuam tshuam.

6. Zoo meej huab cua nruj

Txais kev sib koom ua ke sib tshooj hlau nplhaib los tsim ntau qhov kev sib khi (patent naj npawb: ZL 2014 2 0490187.3) kom lav tsis muaj cov hmoov av los ntawm cov ncej kawg ntawm cov hniav sib xyaw;Hydraulic teb lock tso tawm rooj vag muaj zoo heev huab cua-tightness, sealing nto ntawm uas yeej tsis hnav tawm kom huab cua-tightness yog txhim khu kev qha thiab tsis muaj cov ntaub ntawv los ntawm paug qhov rooj.

7. Ceev ceev, tsis muaj cov khoom seem

Kev sib xyaw cov hniav thawb cov khoom spirally thiab cov khoom yog tawm sai.Lub rooj vag tawm yog nyob rau hauv qab ntawm lub tank, cov khoom tawm tawm tag nrho yam tsis muaj qhov seem, cov khoom siv tawm lub sijhawm tsawg dua 2min, thiab tsis muaj cov khoom seem hauv lub tank.

8. Siab hnav-tiv taus

Sib tov cov hniav yog nto welded nrog hnav-resistant khaubncaws sab nraud povtseg nrog lub rigidity mus txog rau HRC6065, thiab kev pab cuam lub neej ntawm sib tov hniav yog 20 xyoo.Lub tank hauv ob sab phlu siv hom tshiab hnav-resistant manganese steel khoom nrog lub zog zoo tom qab kev kho cua sov.Kev pabcuam lub neej ntawm cov phaj phaj los tsim cov anode yog 15 xyoo thiab nws yog 1 xyoos los tsim cathode thiab carbon electrodes.

9.Bearing qauv ntawm kev sib xyaw hniav yog txhim khu kev qha

Kev sib xyaw ntawm cov hniav sib xyaw siv tus kheej-aligning rau cov menyuam bearing thiab ob-txoj kev thrust bearing tsim uas kov yeej axial quab yuam ntawm kev sib xyaw hniav thiab tiv thaiv kev sib xyaw ntawm axial hloov thiab kev pabcuam lub neej ntawm cov kabmob ntev dua.Bearing qauv yog tsau rau ntawm ib sab thiab txav tau ntawm sab nraud, uas tshem tawm cov kev cuam tshuam ntawm thermal expansion thiab tiv thaiv kev sib xyaw ntawm cov hniav los ntawm kev ntes tom qab nws yog rhuab los ntawm tshav kub hloov roj.

10.Reliable lag luam ntawm kis tau tus mob system

Nws txais yuav cov hniav txo qis gearbox thiab synchronous gearbox phua qauv nrog tag nrho lubrication thiab txhim khu kev qha ua haujlwm.Hard hniav txo iav, bearing muaj peev xwm yog 3 zaug ntawm ib qho, ua ke nrog iav coupling, guarantees siab bearing muaj peev xwm kis tau tus mob.Hydraulic clutch tuaj yeem kho lub zog kis tau tus mob raws li kev thauj khoom los muab kev tiv thaiv overload, thiab tso cai rau lub tshuab rov pib dua nrog kev thauj khoom thaum muaj qee qhov tshwj xeeb (xws li rov pib dua tom qab nres thaum khiav).

11. Tsis muaj suab nrov

Nws yog machined los ntawm cov cuab yeej tshwj xeeb kom tau txais kev pom zoo, ua rau kev ua haujlwm du, kev pabcuam lub neej ntev, thiab lub suab nrov ntawm tag nrho lub tshuab tsawg dua 80dB.

12. PLC tag nrho tsis siv neeg tswj

PLC tswj thiab kev sib txuas lus hauv is taws nem tau txais los ntsuas, tso saib thiab xa cov khoom siv khiav thiab cov xwm txheej ntawm lub sijhawm (optional configuration).Peb hom kev lag luam hom internet tsis siv neeg, ib lub tshuab tsis siv neeg thiab phau ntawv - lav lub tshuab nws tus kheej tuaj yeem khiav tau txawm tias cov tshuab nce thiab nqis qis tsis siv neeg.

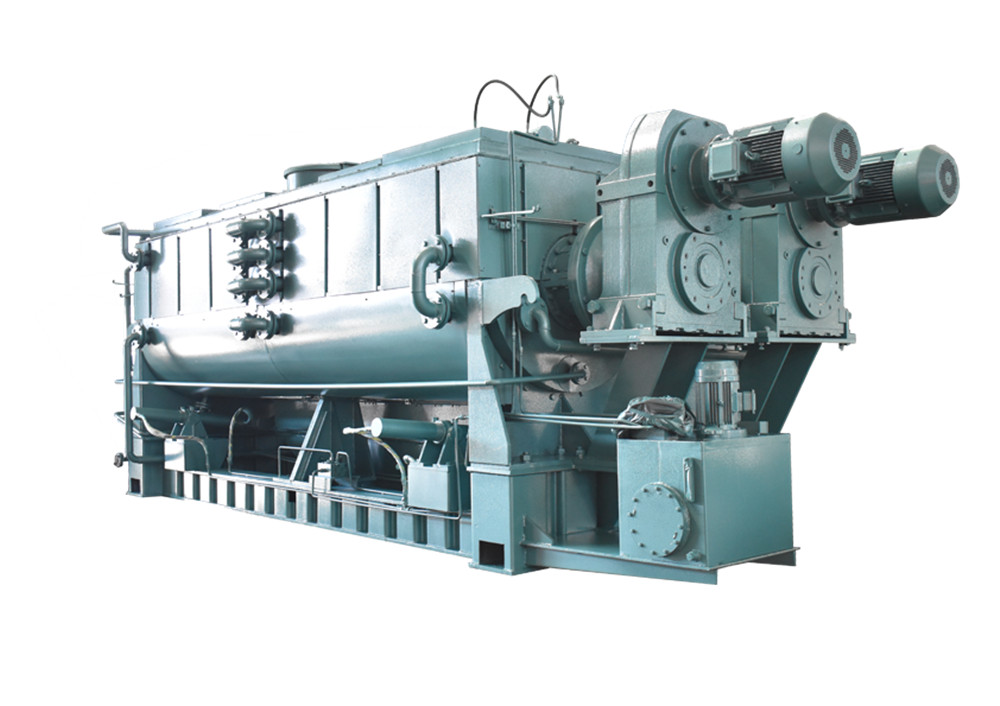

HP-PKC SERIES

CARBON PASTE KNEADERING COOLER

HP-PKC series paste kneading cooler (Invention Patent No 20121099062.3) yog thoob ntiaj teb ua lub tshuab kneading.Nws txais yuav cov tshuab kneading uas tsis tshua muaj kub uas muab tshuaj txhuam yog kneaded dua thaum txias, kneading zoo yog ntxiv txhim kho.Paste tom qab txias s dispersive nrog agglomeration, thiab suab pa taws. yog tag nrho tawm, thiab nws mus txog thoob ntiaj teb cov khoom zoo sib xws.

Kev ua tau zoo

1. Tsawg kub sib tov thiab txias

Txais carbon paste cooler technology (Invention Patent NO.: ZL 2012 1 0099062.3), paste cooler technology (patent No.: ZL 2009 2 0273347.8) los knead nyob rau hauv qis kub thaum txias carbon paste.Tom qab cov pa roj carbon paste yog kneaded thiab txias mus rau 130 ℃ (xws li kub muaj feem xyuam rau cov yam ntxwv ntawm lub suab), nrog rau qhov txo qis ntawm qhov kub thiab txias, qhov tsim ntawm pitch adsorption txheej ntawm aggregate nto yog active, thiab cov txheej txheem ntawm pitch adsorption txheej. zoo li yuav tsum tau teem nyob rau hauv kev txiav txim, uas yog zoo los txhim kho conductivity ntawm carbon cov khoom.

2. Moulding ntim ceev yog txhim kho los ntawm 0.02

Carbon khoom molding thiab tiav cov khoom ntim ntim tau zoo dua los ntawm 0.02 nyob rau hauv tib lub molding mob..

3. Tawm los yog txhim kho los ntawm 2-5%

Carbon cov khoom tsis xws luag raug tshem tawm, tawm los ntawm cov khoom tiav ua los ntawm cov pa roj carbon monoxide txias yog txhim kho los ntawm 2-5% raws li cov txheej txheem tib yam.

4. Tus nqi ntawm lub suab raug txo los ntawm 2%

Pitch noj tus nqi nyob rau hauv lub dhau los "sib tov" txheej txheem ntau lawm yog txo los ntawm ntau tshaj 2%.

5. Txias muab tshuaj txhuam tsis zoo

Cov pa roj carbon paste txias tshuab tau txais los ntawm qhov tshwj xeeb tsim cov hniav sib tov sib xyaw thiab tawg ua kom muaj zog.

6. Cooled carbon paste yog qhov kub thiab txias

Cov pa roj carbon monoxide yog tov thiab txias los ntawm circulating cua txias nruab nrab ib txhij.Ob sib tov hniav tig synchronously tab sis nyob rau hauv opposite kev taw qhia, yog li cov ntaub ntawv ntws nyob rau hauv kev txiav txim nyob rau hauv lub tank, uas homogenize lub paste kub thiab cov cuab yeej, minimize mixing kuj thiab txuag cov cuab yeej tsav tsheb.

7.Cooling efficiency siab

Txais siv cov cuab yeej siv hluav taws xob sib xyaw (patent No.: ZL 2006 20085174.3, cov hniav sib xyaw muaj cov cua txias hauv nruab nrab kom txias txias), tag nrho cheeb tsam cua sov tshuab (patent No.. phaj thiab tank seam-tsawg-fitting thiab lwm yam tshuab cua txias-intensifying.

8. Tshem cov pa luam yeeb kiag li

Qhov tshwj xeeb tsim cov hniav sib xyaw ua kom cov tshuaj txhuam hniav tsis tu ncua kom ua rau nws tsis muaj kev khiav tawm ntawm cov pa luam yeeb yog li nrawm.

9. Kev ntsuas kub yog qhov tseeb

Txais cov cuab yeej ntsuas kub tshiab (patent No. ZL2014 2 0490132.2) txhawm rau txhim kho qhov ntsuas kub ntawm qhov ntsuas kub ntawm qhov ntsuas kub thiab tiv thaiv kev cuam tshuam.

10. Ceev cov khoom tawm, tsis muaj cov khoom seem

Sib tov cov hniav thawb cov ntaub ntawv kauv kom tso cov khoom tawm sai thiab ua tiav los ntawm qhov qhib qhov rooj qhib hauv qis dua 2 min yam tsis muaj qhov seem seem.

11. High hnav tsis kam

Sib tov cov hniav yog nto-welded nrog hnav-resistant khaubncaws sab nraud povtseg, rigidity uas yog mus txog HR6065, thiab kev pab cuam lub neej ntawm sib tov hniav yog 20 xyoo.Hom tshiab hnav-resistant manganese steel cov ntaub ntawv yog siv los ua hauv ob sab phlu nrog lub zog siab tom qab kev kho cua sov.Kev pabcuam lub neej ntawm cov phaj phaj rau anode ntau lawm s15 xyoo thiab 1 xyoo nws yog rau cathode thiab carbon electrode ntau lawm.

12. Cov qauv ntawm cov hniav sib xyaw yog txhim khu kev qha

Kev sib xyaw ntawm cov hniav sib xyaw siv tus kheej-aligning rau cov menyuam bearing thiab ob-txoj kev thrust bearing tsim uas kov yeej axial quab yuam ntawm kev sib xyaw hniav thiab tiv thaiv kev sib xyaw ntawm cov hniav ntawm axial hloov thiab kev pabcuam lub neej ntawm cov kabmob ntev dua.Bearing qauv yog tsau rau ntawm ib sab thiab txav tau ntawm sab nraud, uas tshem tawm cov kev cuam tshuam ntawm thermal expansion thiab tiv thaiv kev sib xyaw ntawm cov hniav los ntawm kev ntes tom qab nws yog rhuab los ntawm tshav kub hloov roj.

13. Txhim khu kev ua haujlwm

Nws txais yuav nyuaj cov hniav txo gearbox thiab synchronous iav-lub thawv cais qauv nrog tag nrho lubrication thiab txhim khu kev qha lag luam.Hard hniav txo iav, bearing muaj peev xwm yog 3 zaug ntawm ib qho, ua ke nrog iav coupling, guarantees siab bearing muaj peev xwm kis tau tus mob.Hydraulic clutch tuaj yeem kho lub zog kis tau tus mob raws li kev thauj khoom los muab kev tiv thaiv overload, thiab tso cai rau lub tshuab rov pib dua nrog kev thauj khoom thaum muaj qee qhov tshwj xeeb (xws li rov pib dua tom qab nres thaum khiav)

14. Tsis muaj suab nrov

Nws yog machined los ntawm cov cuab yeej tshwj xeeb, kom tau zoo concentricity, ua rau lub lag luam du, kev pab cuam lub neej ntev, thiab lub lag luam nrov nrov ntawm tag nrho cov tshuab tsawg tshaj li 80dB.

15. PLC tag nrho tsis siv neeg tswj

PLC tswj thiab kev sib txuas lus hauv is taws nem tau txais los ntsuas, tso saib thiab xa cov khoom siv khiav thiab cov xwm txheej ntawm lub sijhawm (optional configuration).Peb hom kev lag luam hom --- internet tsis siv neeg, ib lub tshuab tsis siv neeg thiab phau ntawv..guarantee lub tshuab nws tus kheej tuaj yeem ua haujlwm tau txawm tias cov tshuab ntws thiab qis qis tsis siv neeg.